How We Work

Reach us

Like and follow our Facebook page for more updates !

Like and follow our Instagram page for more updates !

Like and follow our YouTube channel for more updates !

Like and follow our TikTok account for more updates !

Drop us an email if you have any questions regarding our products, or if you any general enquiries such as private engagements, corporate training, advertising offers, job applications, or partnership opportunities. We will get back to you as soon as we can.

Fax +603 7831 1179

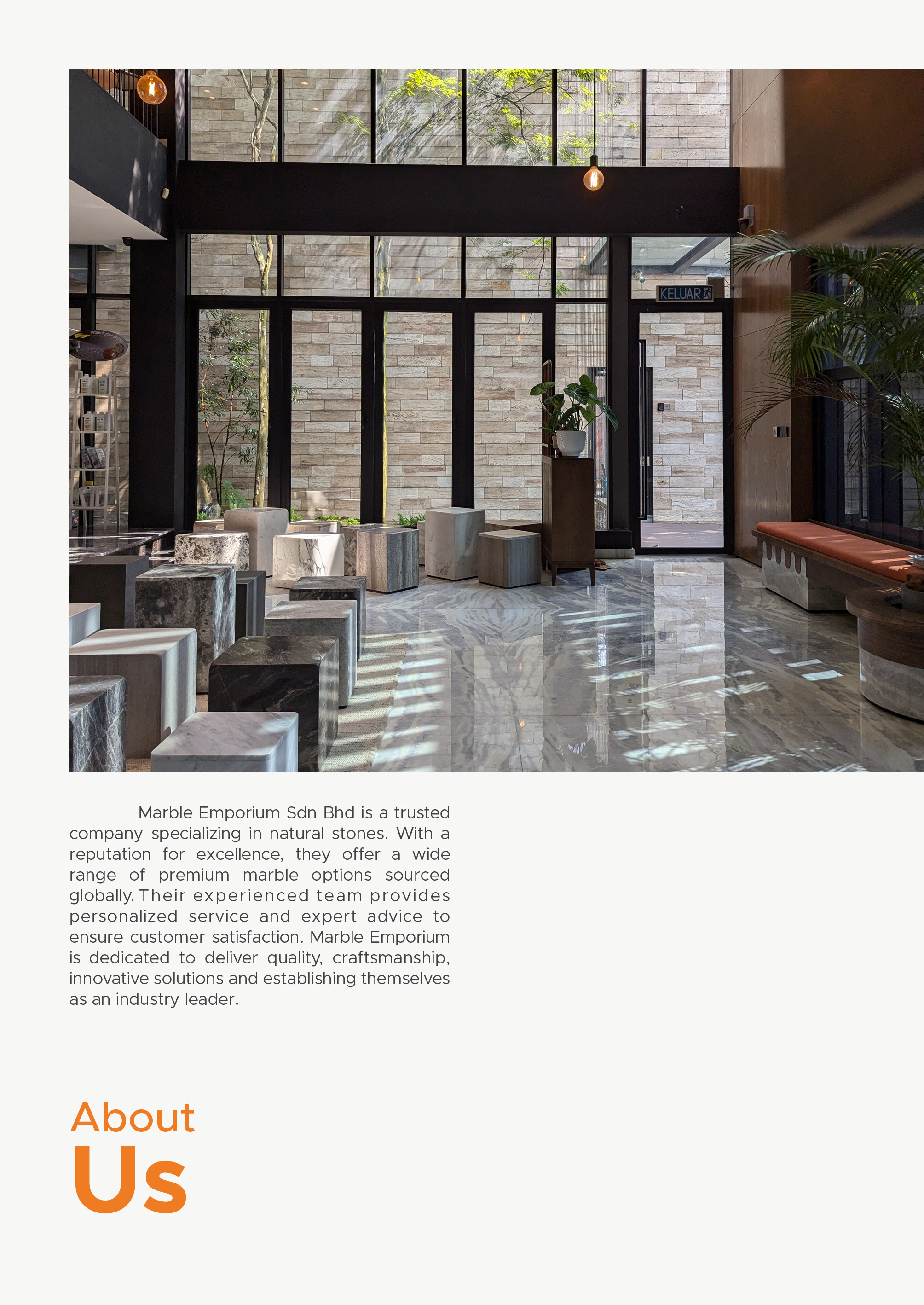

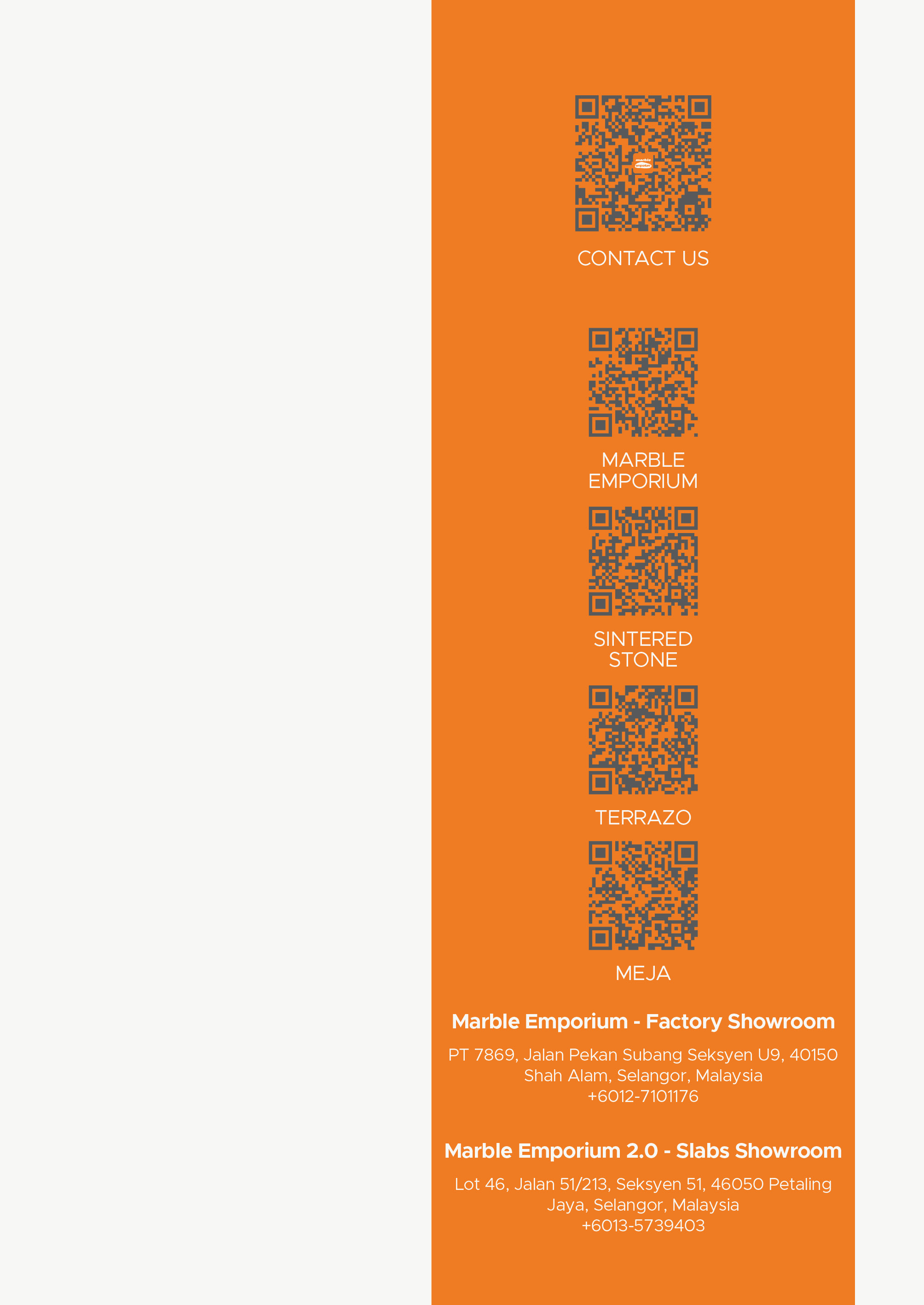

Our Showroom

Marble Emporium Sdn Bhd

(Monterez Golf & Country Club)

PT 7869, Jalan Pekan Subang Seksyen U9, 40150 Shah Alam, Selangor, Malaysia

Monday - Saturday : 10:00AM - 5:00PM

Sunday & Public Holiday : Closed

Showroom @ Petaling Jaya

Marble Emporium 2.0

Lot 46, Jalan 51/213, Seksyen 51,

46050 Petaling Jaya, Selangor.

Monday - Saturday : 10:00AM - 4:30PM

Sunday & Public Holiday : Closed

Contact Us

Our Showroom

Marble Emporium Sdn Bhd 700361-H

(Monterez Golf & Country Club)

PT 7869, Jalan Pekan Subang Seksyen U9

40150 Shah Alam, Selangor, Malaysia

Monday-Saturday : 10:00AM - 5:00PM

Sunday & Public Holiday : Closed

Marble Emporium 2.0

Lot 46, Jalan 51/213, Seksyen 51,

46050 Petaling Jaya, Selangor.

Monday-Saturday : 10:00AM - 4:30PM

Sunday & Public Holiday : Closed

| Tel | +603 7832 1126 |

| H/P | +6012 219 3228 |

| H/P | +6012 710 1176 |

| Fax | +603 7831 1179 |

| info@marbleemporium.com.my |

Developed by E STYLE CREATION